You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

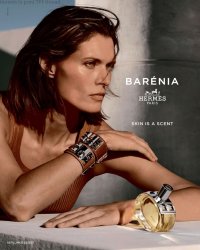

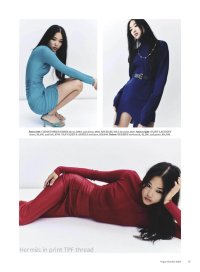

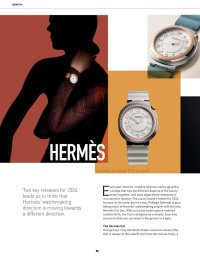

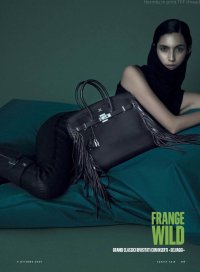

Hermes in print

- Thread starter HiHeels

- Start date

TPF may earn a commission from merchant affiliate

links, including eBay, Amazon, and others

More options

Who Replied?Hermès Unveils New Leather Goods Factory in Auvergne

The 79,000-square-foot facility in central France will focus on producing Birkin and Constance bags and employ 250 artisans.September 13, 2024, 6:00am

RIOM, France — Despite the ongoing luxury slowdown, Hermès shows no sign of reining in its production.

The maker of Birkin bags and silk squares on Friday inaugurated its latest leather goods factory.

Chief executive officer Axel Dumas cut the ribbon on a facility spanning 79,000 square feet in Riom, a city of 19,000 residents in Auvergne, a region in central France.

“It’s a moment that never stops moving me because it hasn’t been easy,” he said at the ceremony. “When I was young, we had 250 craftspeople, didn’t sell any Kelly [bags] and hadn’t even invented the Birkin. So it was harder but we persevered although craftsmanship in the industrial ’70s and ’80s interested absolutely no one.”

Times have changed. Riom is the company’s 23rd leather goods workshop in France and the 12th to open since 2010.

While other luxury companies have been seeing lackluster results in the first half of 2024, Hermès is riding what Dumas deemed a “flight to quality” during an analyst call on second-quarter results in July.

The company reported double-digit gains in all regions, achieving an 11.5 percent increase in revenues in the second quarter to 3.7 billion euros. Leather goods were among the strongest performers of the period, logging 17.9 percent organic growth.

The Birkin and Constance models will be the focus of the factory in Riom.

While no figure was given for the number of items the facility can produce, it takes 15 to 20 hours to make one purse. Fully trained artisans can produce between two and three a week.

“Thanks to the new factories or extension plans [in existing ones], we are looking at 6 to 7 percent of growth in volume a year,” said Guillaume de Seynes, Hermès’ executive vice president, manufacturing division and equity investments.

While that may not sate the global appetite for its sought-after purses, he reiterated that there was no artificial scarcity at play.

“We try to ramp up production at a rapid pace but we are staying on the artisanal model which is synonmyous with quality in our opinion,” he said. “We aren’t about to start going for productivity gains.”

Hermès took over one wing of the Manufacture des Tabacs de Riom, a former tobacco factory built in the 19th century, with successive extensions bringing the total surface to nearly 10 acres.

Closed in 1975, it became a listed historical venue in 2004. The majority of the site has been rehabilitated for private housing and also hosted artistic residences. A number of graffiti murals left by the artists have been preserved by the luxury company.

Courtesy of Hermès

Renovation of the two buildings forming the Hermès facility was entrusted to Paris-based firm Tracks-Architectes, which describes its approach as a frugal one rooted in the existing environment around each project.

Features such as Tyrolean renderings on the facades, windows made of the region’s gray-blue volcanic stone and slate roofs were cleaned or restored to their original condition.

Glass and transparency were favored for contemporary elements such as continuous glass roofs, the patio and awnings, as well as a bridge between buildings.

A key requirement was letting natural light reach the heart of the workshops, which are the first to be arranged in a multilevel layout.

Ahead of the opening, artisans demonstrated their skills at cutting, assembling and sewing in their airy workspaces, and visitors were even invited to try their hand at sewing the famous saddle stitch.

Salvaged materials were used for the planted courtyard, which hides rainwater retention and treatment basins. Garden furniture is also made from segments of concrete beams and steel sleepers.

While it isn’t eligible for the E4C2 certification awarded to Louviers, which distinguishes new builds with a lowered carbon footprint that are energy positive, Riom marks the third time Hermès has overhauled existing buildings.

“It is our plan, and works are already underway on a number of buildings, to increase the energy efficiency of older constructions,” de Seynes said. The nearby 20-year-old Sayat leather goods facility is among those soon to be overhauled.

According to the executive, Hermès is increasingly moving toward rehabilitation projects for its new sites, both to anticipate possible regulations against artificialization of land but also as part of a broader commitment toward revitalizing urban centers affected by the loss of other industries.

The implantation in Riom also created a hub with the Sayat factory, a grouping strategy the company has rolled out in nine regions in France to boost the attraction for recruitment as well as aid training and skill preservation.

Such poles could have up to three factories but no larger facilities, as Dumas deemed 300 people per factory the “golden number” to preserve interpersonal relationships and “human-sized” facilities.

In the Auvergne region, Hermès is working with local employment and adult education services as well as a nearby vocational high school. It also has a branch of its École Hermès des Savoir-faire in the region, which is accredited by the French Ministry of Education to deliver state-recognized qualifications.

Despite the slowdown in consumption, particularly in China, de Seynes said the company had not changed its long-term investment plans in light of continued strong demand for its bags and leather goods.

Riom follows the opening of factories in Louviers, focusing on its famous Kelly purse; Tournes in northern France, and the expansion of its Pierre-Bénite silk-focused atelier near Lyon, and the Saint Junien handbag and glove facility in the New Aquitaine region of France.

Three more facilities are in the works. Earlier this year, de Seynes laid the foundation stone for factories in L’Îsle-d’Espagnac in Charente, which is slated to go onstream in 2025, and Loupes, a town near Bordeaux, slated for 2026.

Another site in Charleville-Mezières, located near the border with Belgium in the French Ardennes region, is on the plan for 2027.

“We are also investing in a number of domains, both in terms of capacity but also with performance upgrades such as energy efficiency or [decreasing] water consumption in tanneries,” de Seynes said.

Plans for a site producing procelain as well as enamel have been made near Limoges.

Separately, Dumas also said the company would be extending its existing perfume factory in Normandy and add a new site, although he did not provide a timeline for the project.

Hermès counts 60 production sites in France, with around 7,300 artisans across the country. It also produces in nearby countries, such as watches made in its Switzerland-based factories and ready-to-wear in Italy.

The CEO sidestepped questions on whether the company would consider producing some of its goods in the U.S.

“I’m not closed to anything. What matters to me is being in a place where there is real know-how and historic know-how,” said Dumas, pointing out France’s leather goods and silk expertise, handweaving in Nepal or lacquer in Vietnam. “I’m ready to try and find the most beautiful materials and know-how where they are.”

Hermès Unveils New Leather Goods Factory in Auvergne

Hermès inaugurated a new 79,000-square-foot factory in central France that will focus on the Birkin and Constance handbags as well as leather goods.

Hermès Unveils New Leather Goods Factory in Auvergne

The 79,000-square-foot facility in central France will focus on producing Birkin and Constance bags and employ 250 artisans.

September 13, 2024, 6:00am

Hermès' leather goods factory in Riom is the first to have workshops on multiple levels. Courtesy of Hermès

RIOM, France — Despite the ongoing luxury slowdown, Hermès shows no sign of reining in its production.

The maker of Birkin bags and silk squares on Friday inaugurated its latest leather goods factory.

Chief executive officer Axel Dumas cut the ribbon on a facility spanning 79,000 square feet in Riom, a city of 19,000 residents in Auvergne, a region in central France.

“It’s a moment that never stops moving me because it hasn’t been easy,” he said at the ceremony. “When I was young, we had 250 craftspeople, didn’t sell any Kelly [bags] and hadn’t even invented the Birkin. So it was harder but we persevered although craftsmanship in the industrial ’70s and ’80s interested absolutely no one.”

Times have changed. Riom is the company’s 23rd leather goods workshop in France and the 12th to open since 2010.

While other luxury companies have been seeing lackluster results in the first half of 2024, Hermès is riding what Dumas deemed a “flight to quality” during an analyst call on second-quarter results in July.

The company reported double-digit gains in all regions, achieving an 11.5 percent increase in revenues in the second quarter to 3.7 billion euros. Leather goods were among the strongest performers of the period, logging 17.9 percent organic growth.

The Birkin and Constance models will be the focus of the factory in Riom.

While no figure was given for the number of items the facility can produce, it takes 15 to 20 hours to make one purse. Fully trained artisans can produce between two and three a week.

“Thanks to the new factories or extension plans [in existing ones], we are looking at 6 to 7 percent of growth in volume a year,” said Guillaume de Seynes, Hermès’ executive vice president, manufacturing division and equity investments.

While that may not sate the global appetite for its sought-after purses, he reiterated that there was no artificial scarcity at play.

“We try to ramp up production at a rapid pace but we are staying on the artisanal model which is synonmyous with quality in our opinion,” he said. “We aren’t about to start going for productivity gains.”

Hermès took over one wing of the Manufacture des Tabacs de Riom, a former tobacco factory built in the 19th century, with successive extensions bringing the total surface to nearly 10 acres.

Closed in 1975, it became a listed historical venue in 2004. The majority of the site has been rehabilitated for private housing and also hosted artistic residences. A number of graffiti murals left by the artists have been preserved by the luxury company.

Courtesy of Hermès

Renovation of the two buildings forming the Hermès facility was entrusted to Paris-based firm Tracks-Architectes, which describes its approach as a frugal one rooted in the existing environment around each project.

Features such as Tyrolean renderings on the facades, windows made of the region’s gray-blue volcanic stone and slate roofs were cleaned or restored to their original condition.

Glass and transparency were favored for contemporary elements such as continuous glass roofs, the patio and awnings, as well as a bridge between buildings.

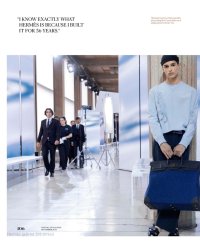

A key requirement was letting natural light reach the heart of the workshops, which are the first to be arranged in a multilevel layout.

Ahead of the opening, artisans demonstrated their skills at cutting, assembling and sewing in their airy workspaces, and visitors were even invited to try their hand at sewing the famous saddle stitch.

Salvaged materials were used for the planted courtyard, which hides rainwater retention and treatment basins. Garden furniture is also made from segments of concrete beams and steel sleepers.

While it isn’t eligible for the E4C2 certification awarded to Louviers, which distinguishes new builds with a lowered carbon footprint that are energy positive, Riom marks the third time Hermès has overhauled existing buildings.

“It is our plan, and works are already underway on a number of buildings, to increase the energy efficiency of older constructions,” de Seynes said. The nearby 20-year-old Sayat leather goods facility is among those soon to be overhauled.

According to the executive, Hermès is increasingly moving toward rehabilitation projects for its new sites, both to anticipate possible regulations against artificialization of land but also as part of a broader commitment toward revitalizing urban centers affected by the loss of other industries.

The implantation in Riom also created a hub with the Sayat factory, a grouping strategy the company has rolled out in nine regions in France to boost the attraction for recruitment as well as aid training and skill preservation.

Such poles could have up to three factories but no larger facilities, as Dumas deemed 300 people per factory the “golden number” to preserve interpersonal relationships and “human-sized” facilities.

In the Auvergne region, Hermès is working with local employment and adult education services as well as a nearby vocational high school. It also has a branch of its École Hermès des Savoir-faire in the region, which is accredited by the French Ministry of Education to deliver state-recognized qualifications.

Despite the slowdown in consumption, particularly in China, de Seynes said the company had not changed its long-term investment plans in light of continued strong demand for its bags and leather goods.

Riom follows the opening of factories in Louviers, focusing on its famous Kelly purse; Tournes in northern France, and the expansion of its Pierre-Bénite silk-focused atelier near Lyon, and the Saint Junien handbag and glove facility in the New Aquitaine region of France.

Three more facilities are in the works. Earlier this year, de Seynes laid the foundation stone for factories in L’Îsle-d’Espagnac in Charente, which is slated to go onstream in 2025, and Loupes, a town near Bordeaux, slated for 2026.

Another site in Charleville-Mezières, located near the border with Belgium in the French Ardennes region, is on the plan for 2027.

“We are also investing in a number of domains, both in terms of capacity but also with performance upgrades such as energy efficiency or [decreasing] water consumption in tanneries,” de Seynes said.

Plans for a site producing procelain as well as enamel have been made near Limoges.

Separately, Dumas also said the company would be extending its existing perfume factory in Normandy and add a new site, although he did not provide a timeline for the project.

Hermès counts 60 production sites in France, with around 7,300 artisans across the country. It also produces in nearby countries, such as watches made in its Switzerland-based factories and ready-to-wear in Italy.

The CEO sidestepped questions on whether the company would consider producing some of its goods in the U.S.

“I’m not closed to anything. What matters to me is being in a place where there is real know-how and historic know-how,” said Dumas, pointing out France’s leather goods and silk expertise, handweaving in Nepal or lacquer in Vietnam. “I’m ready to try and find the most beautiful materials and know-how where they are.”

Hermès Unveils New Leather Goods Factory in Auvergne

Hermès inaugurated a new 79,000-square-foot factory in central France that will focus on the Birkin and Constance handbags as well as leather goods.wwd.com

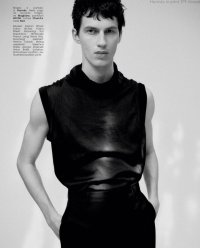

what a very attractive artisan

Register on TPF! This sidebar then disappears and there are less ads!